Confined Spaces: Hazards of Manure Gases

Confined space: Hazards of manure gases. (2012) Farm and Ranch eXtension in Safety and Health (FReSH) Community of Practice. Retrieved from http://www.extension.org/pages/63141/confined-spaces:-hazards-of-manure-….

The Occupational Safety and Health Administration (OSHA) defines a confined space as a space that:- is large enough for a worker to enter and complete a task in,

- has limited or restricted means of entry or exit, and

- is not designed for continuous human occupancy.

Confined spaces on a farm or ranch in which manure handling may occur include manure pits, manure transfer pipes and deep gutters, transfer storage areas, and liquid manure spreaders. Farms and ranches continue to expand their operations to include larger manure handling systems. While these new systems are more efficient and reduce manual labor, farmers and ranchers must understand the hazards associated with working in and around confined spaces where manure is stored.

Gases inside Manure Storage AreasThe breakdown of manure is a biological process, and environmental factors such as temperature, humidity, and air flow can impact the release rate of gases produced during this process. High temperature, lack of air exchange, and humidity can increase the levels of manure gases that are produced and released. The following hazardous gases form naturally in manure storage areas and are difficult to detect because of their properties, impact on a person's sense of smell, and similarity to other odors on a farm or ranch:

- Ammonia is found in manure pits or aboveground tanks used for manure storage and has a strong odor that can irritate a person's eyes or respiratory system.

- Carbon dioxide is a colorless and odorless gas associated with animal respiration and manure decomposition. Carbon dioxide can replace the oxygen in a confined space. If you breathe in air that contains high levels of carbon dioxide, this gas can replace the oxygen in your bloodstream and may result in headaches, drowsiness, and death (after prolonged exposure). Carbon dioxide is heavier than air, so it can easily accumulate in low-lying areas of confined spaces.

- Hydrogen sulfide is a colorless gas that smells like rotten eggs at low levels but can overcome a person's sense of smell at levels of 100 ppm and higher. Exposure to hydrogen sulfide can cause eye and nose irritation, headache, nausea, and death (after prolonged exposure). Hydrogen sulfide is heavier than air, so it can easily accumulate in low-lying areas of confined spaces.

- Methane is a colorless and odorless gas produced during the decomposition of manure in storage. This gas is flammable and potentially explosive, especially when captured in foam that can form on the surface of stored manure. Methane is lighter than air, so it does not accumulate in low-lying areas of confined spaces.

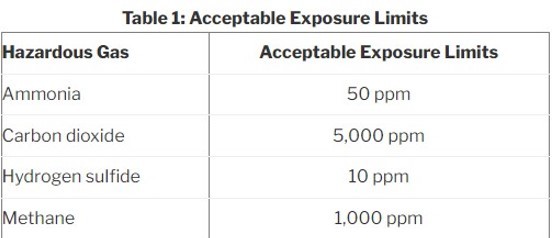

For each of the hazardous gases mentioned above, OSHA has identified safe exposure levels for humans. Table 1 outlines the acceptable exposure limits in ppm over an eight-hour period. The oxygen level in a given space should be between 19% and 23%.

One way to reduce levels of hazardous gases is to ventilate the manure storage area using a mechanical ventilation system that forces fresh air into the space, increasing the oxygen level and decreasing the levels of explosive and toxic gases. By using a specially designed positive-pressure mechanical forced-air ventilation system, you can reduce the buildup of dangerous levels of gas. Forcing fresh air through a fan into the storage area reduces the possibility of fire or explosion caused by explosive gas coming into contact with electric fan motors. Fans should be able to move a volume of air equal to one-half the volume of the empty manure storage area every minute. Use the ANSI/ASABE S607 standard, provided by the American National Standard Institute (ANSI) and American Society of Agricultural and Biological Engineers (ASABE), for guidance about ventilation capacity and ventilation time prior to entry and during occupancy. To avoid the failure of a critical ventilation system during a power outage, connect the system to a standby power source that is regularly maintained and tested.

Entering Confined-Space Manure Storage Areas

If possible, avoid entering confined-space manure storage areas. If entry is unavoidable, you should fully understand the risks of entering such a space and have an entry plan that outlines your actions.

Complete the following steps when entering and working in a confined-space manure storage area:- Test the oxygen and explosive and toxic gas levels from outside the manure storage area.

- Prior to entry and during occupancy, use a positive-pressure ventilation system to ventilate the manure-storage area.

- Prior to entry, lock out all power sources other than the positive-pressure ventilation system to reduce the risk of stray electricity.

- Wear an adjustable body harness with a lifeline attached to a rescue and retrieval system and carry a portable gas monitor.

- Assign a second person to remain outside of the manure-storage area in case he or she must implement the rescue and retrieval system or get additional assistance.

- Maintain verbal and visual contact with the person outside the manure storage area. The person outside the storage area should not enter the area, even in the event of an emergency.

- Retest the air quality continuously during occupancy to monitor gas levels.

Additional Safety Recommendations

- Remember that youth under the age of 16 are prohibited from working in confined spaces.

- Post warning signs about the risks of confined spaces and gas hazards on or near all manure storage locations.

- Instruct family members and employees about the hazards associated with manure storage in confined spaces. Even though most agricultural operations are not covered under OSHA regulations for confined-space entry, confined spaces exist in production agriculture, and it is vital that every person associated with the farm or ranch receive training on the hazards.

- Prepare and document an entry plan for confined-space manure storage areas. Inform family members and employees about the plan.

- Provide annual training for family members and employees about the entry into and emergency procedures associated with confined manure storage spaces.

- Restrict access to confined spaces to authorized individuals. Remove temporary access ladders, and restrict access to permanent ladders.

- Be aware that personnel and animals may need to vacate the confinement building during manure storage agitation or pumping.

- Prohibit smoking in and around manure storage areas.

- Operate manure agitators below the surface of liquid manure to reduce the release of manure gases.

Sources

Confined spaces. (n.d.) United States Department of Labor. Retrieved from http://www.osha.gov/SLTC/confinedspaces/index.html.

Harshman, W., Yoder, A., Hilton, J., & Murphy, D. (2004) Confined spaces. HOSTA task sheet 3.8. National Safe Tractor and Machinery Operation Program. Retrieved from http://www.extension.org/sites/default/files/NSTMOP%20Task%20Sheets%20Se….

Harshman, W., Yoder, A., Hilton, J., & Murphy, D. (2004) Manure storage. HOSTA task sheet 3.11. National Safe Tractor and Machinery Operation Program. Retrieved from http://www.extension.org/sites/default/files/NSTMOP%20Task%20Sheets%20Se….

Steel, J., Murphy, D., & Manbeck, H. (2011) Confined space manure storage hazards. Penn State Extension. Retrieved from https://extension.psu.edu/confined-space-manure-storage-hazards.

Zhao, L. (2007) How to work safely around manure storage. Ohio State University Extension. No longer available online.

Upcoming Events

NY Pork Producers - 2026 Producer Summit & Annual Meeting

March 13 - March 14, 2026

Hamilton, NY

Join NYPP for the 2026 Producer Summit, where producers of all sizes and production styles will explore marketing, branding, selling pork, and current consumer trends through practical sessions designed to help build demand, connect with customers, and add value to their operations.

Mid Atlantic Grain Conference

March 15 - March 16, 2026

We're excited to share that the 2026 Mid‐Atlantic Grain Fair & Grain Conference is coming March 15-16, 2026 in Pennsylvania! This two-day event brings together farmers, millers, bakers, brewers, distillers, researchers, and grain enthusiasts to learn, connect, and celebrate local grains. These events will be offered at two seperate locations.

Quality Wool Workshop

March 21, 2026

Alfred, NY

Please join us for a day of workshops and hands-on activities for shepherds, shearers, fiber artists, and interested community members -- learn how to produce quality fleece, process wool at-home, access markets for your wool, help your local shepherds, and strengthen our regional wool supply chain! Hosted by Cornell Cooperative Extension Allegany County in collaboration with Allegany Fresh Transport, Northeast Fiber Exchange (NEFX), Southern Tier Fiber Arts Guild, and Crooked Lane Farm. The workshop will be held at the Union University Church Community Center in Alfred, NY on Saturday, March 21st from 10 AM to 4 PM.

Announcements

No announcements at this time.