Evaluating Feeding Management to Boost Cow Productivity

Camila Lage, Dairy Management Specialist

Southwest New York Dairy, Livestock and Field Crops Program

Evaluating Feeding Management to Boost Cow Productivity

By Camila Lage, Dairy Management Specialist

Have you ever heard the saying, "You can't manage what you can't measure"? Well, I had, and not too long ago, I had a firsthand experience that reinforced it. Last March, I sought guidance from my dietitian, Carla, to help me refine my eating habits. She prescribed me a diet plan, and I was excited to implement it. However, as weeks passed, I noticed clothes fitting more snugly, and I felt heavier. I couldn't understand it. I had diligently followed the diet plan, consisting of all the right foods. I scheduled a new consultation and shared my weight gain concerns with Carla. She did not seem concerned and asked me to do something seemingly simple - use a kitchen scale and a food app to track everything I consumed. Over the next few weeks, I logged every meal, snack, and drink. Not surprisingly, I had followed the plan, but my portion sizes were WAY OFF. I had been underestimating the quantity of what I was eating. "Eyeballing" my portion sizes tricked me. This experience was a humbling reminder that even someone studying animal nutrition and feeding management for so long can overlook the importance of accurate measurements.

But what does this have to do with cows?

Similarly, in my experience, even the more experienced feeders can be deceived by gradual shifts in forage composition, equipment wear, and other factors. We often say that there are three diets on a farm:

1) The formulated: Formulated by the nutritionist with available ingredients to meet cows' requirements.

2) The mixed and delivered diet: Subjected to daily variation due to human error, equipment problems, daily forage variations, weather, and other issues. If following best practices in feeding management, it should be as similar as possible to the one formulated.

3) The Diet Consumed by Cows: Like humans, cows also have preferences when it comes to eating. If the TMR is not well mixed or cows can sort it out, the composition of the diet consumed by each cow will vary. In addition to not being sortable, for cows to eat the formulated diet, they also need good access to the feed bunk, fresh feed, and feed they can reach available for at least 22 hours/day.

Our goal is to minimize the variation between those three diets, and the best way to evaluate it is to perform a systematic assessment of the feeding process. This can be done periodically (perhaps annually or as necessary) when you are training a new feeder or whenever you think there is a problem with the feeding management. This is often called a feeding assessment, which encompasses having an outside person observe and evaluate various aspects of feeding management and cow productivity, including infrastructure, equipment, feeding ingredients, feed bunk, and cow behavior.

The main points that can affect optimal feed management and that are evaluated on feed assessments include:

Figure 1. Minimizing the variation between the formulated diet, the one mixed by the feeder, and the one eaten by the cow.

1) Feed mixer equipment maintenance: Regularly assessing TMR mixer equipment is very important, as minor issues like worn parts and dull knives can impede proper forage processing and mixing. Dairy farms should institute regular maintenance programs, typically after around 500 loads.

2) Feeding consistent forages: Forage within a bunker silo varies. To minimize this variation, forages should first be defaced (starting from the bottom and working up), then pushed into a central pile with the loader bucket and mixed with the bucket. Forages should be premixed before feeding or collecting a sample for analysis. Moldy and rotting feed and hay can cause indigestion and reduced intake. Avoid the feeding of spoiled feed. However, keep in mind that the feeder's safety is always a priority. If taking out all bad feed means putting someone at risk, it must be reevaluated.

3) Hay /straw quality and processing: Hay and straw should be processed to less than 2" to minimize sorting. If evaluating it with the Penn State Particle Size Separator, a reasonable distribution of straw would be approximately 1/3, 1/3, and 1/3 on the top screen, middle screen, and pan. Processing them before loading is best to ensure the correct particle size distribution.

4) Load size, position, and level of the mixer during mixing: Using the mixer at 70% capacity is ideal to ensure proper mixing. Overloading can increase shrinkage because feed can be spilled out, but it can also reduce mixing efficiency. Observe the mixer's action. The feed should be actively moving in all visible areas of the feed load. In addition, make sure the mixer is leveled. When loading the mixer, ensure you are targeting the loader bucket for the center of the feed mixer. This assists in uniform feed distribution.

5) Mixer auger speeds & Hay restrictor plate settings: Regardless of the type of mixer, TMR consistency will be enhanced when the auger speed is increased. Restrictor plates force the TMR closer to the drill, improving the cutting action of knives. However, they also decrease the mixing action within the mixer. If the mixer is not used to process forage, the restrictor plates can be set out on most mixer wagons.

6) Loading sequence: In general, lower density and large particle feeds (straw, hay) is loaded first, followed by dry grains, wet by-products, haylage, corn silage, and liquids. Haylage can be loaded first if clumps are present, and a longer mix time is desired to break it down. However, the best way to break down haylage clumps is with a defacer. If liquid is added, it should last so they are dispersed over the central half to two-thirds of the mixer.

Figure 2. Scheme showing ideal loading order

7) Mix time after the last ingredient: Utilize a timer to monitor the mixing time, as most mixers require about 4 minutes at full power (1700 to 2000 RPM engine speed) for proper mixing.

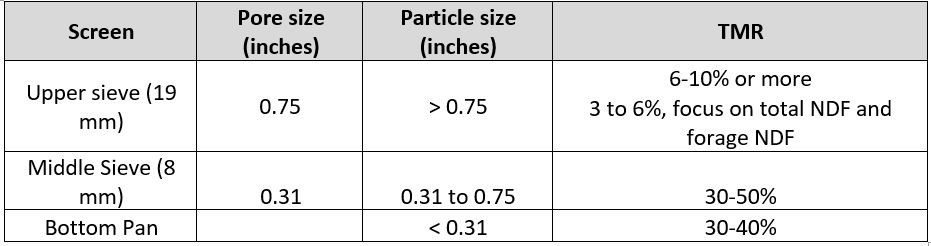

8) Evaluating TMR mixing and consistency: Ten TMR samples should be collected equally spaced along the feed bunk to evaluate proper mixing and TMR particle size distribution. TMR samples are run through the Penn State Particle Separator (2 screens and pan) as recommended. The particle size distributions are graphed, and the coefficient of variation for each screen and the pan is determined. We aim for the coefficient of variation (CV) to be less than 2.5% for the middle screen and pan. The top screen often has much less material, so having a small CV can be more challenging. The recommended distribution of particle size (percent remaining on each screen) for TMR samples is shown in the table below. However, check with your nutritionist for the individual recommendations for your farm.

9) Feed Bunk Management: The delivery of fresh feed is the biggest drive to cow feeding. Research shows a benefit to coordinating new feed delivery with a return from the milking parlor. Feeding cows more than once a day and frequent feed push-ups can also improve intake patterns.

Table 1. Recommended distribution of particle size (percent remaining on each screen) for TMR samples

Source:file:///C:/Users/cd546/Downloads/guidelines-and-graphing-paper-for-2-sieve-particle-separator.pdf (accessed on 10/20/2023)

Figure 3. Example of the use of the Penn State Particle Size Separator

Supporting dairy producers in enhancing their competitive edge is a priority for nutrition teams across the United States. Since feed costs constitute nearly half of the expenses on dairy farms, effective feeding management is crucial, particularly during elevated commodity prices. Different companies and independent nutritionists offer farm audits to farmers. Alternatively, your local dairy extension can also help you with it.

These evaluations result in good information across different feeding areas. The subsequent report identifies operational bottlenecks and opportunities for improvement on the dairy farm. Furthermore, the evaluators offer recommendations for short-, medium--, and long-term strategies, fostering improved practices across the dairy industry.

For additional information or to discuss how to evaluate your feeding program, please do not hesitate to contact Camila Lage at cd546@cornell.edu or 607-422-6788.

Source:

https://extension.psu.edu/penn-state-particle-separator

https://bovine-ojs-tamu.tdl.org/AABP/article/view/3426

Upcoming Events

IPM Strategies to Protect Corn and Soybean Seed in NY

July 30, 2025

Hamburg , NY

SWNYDLFC and Cornell IPM are hosting a grower meeting to discuss integrated pest management strategies for protecting corn and soybean seed in New York.

FAMACHA Training for Sheep and Goat producers in Woodhull NY

August 13, 2025 : FAMACHA Training in Woodhull

Woodhull, NY

Join us for a discussion and hands-on training for internal parasite integrated pest management in sheep and goats. Certification is available to all students participating in the workshop.

Cover Crop & Soil Health Field Day

August 13, 2025

Andover, NY

Please join us for a morning of hands-on learning with expert insights from local farmers, industry representatives, and extension. We will have some demonstration plots in action along with discussion about how cover crops influence soils and demonstration showing impacts on farm resiliency.

Announcements

No announcements at this time.